Introduction

If well shut-in is not sufficient using capping, the Containment Toolkit can be deployed that, when combined with standard industry hardware, can create a containment system designed to flow hydrocarbons from a wellhead to the surface in a safe and controlled way, ready for storage or disposal.

From the capping stack, hydrocarbons are directed through the flowline end termination (FLET) via a flexible jumper. From the FLET, the flow continues through a flexible flowline and the flow-spool assembly into a standard well testing riser and up to a mobile offshore drilling unit (MODU). Well hydrocarbons are processed in the standard surface well testing equipment and part of this (transfer and incinerator pumps + coolers) is included within the containment toolkit, stabilised and then offloaded to a tanker positioned at a safe distance from an incident well.

To maintain flow assurance, hydrate inhibitor can be supplied via a coiled tubing spread installed on a marine vessel to a coiled tubing termination head (CTTH) and onward to the chemical distribution assembly (CDA). The hydrate inhibitor can be delivered to the FLET and capping stack via the CDA.

The containment toolkit is stored in strategic locations to facilitate timely response around the world. Three sets of non-airfreightable flexible subsea jumpers and flowlines are stored in the UK, Brazil and Singapore ready for onward transportation. All other containment toolkit components are both sea and air-freightable and stored response ready in the UK, Norway and USA.

Logistics planning guidelines

Specification

| Water depth | Up to 3,000m |

| H2S content | 0 to 500ppmV |

| Design temperature (operation) | -1°C to 130°C |

| CO2 content | 0 to 10 mol % |

| Max temperature | 130 ̊C (operation) |

| Design operating life | 2 x 6 month deployments |

| Design temperature (storage) | -20°C to 40°C |

| Transportability | Air (Boeing 747-400 ERF; excluding flexible flowlines), land and sea |

| Containment toolkit storage life | 20 years |

Media

Capping and Containment Concept (Long)

Capping and Containment Concept (Short)

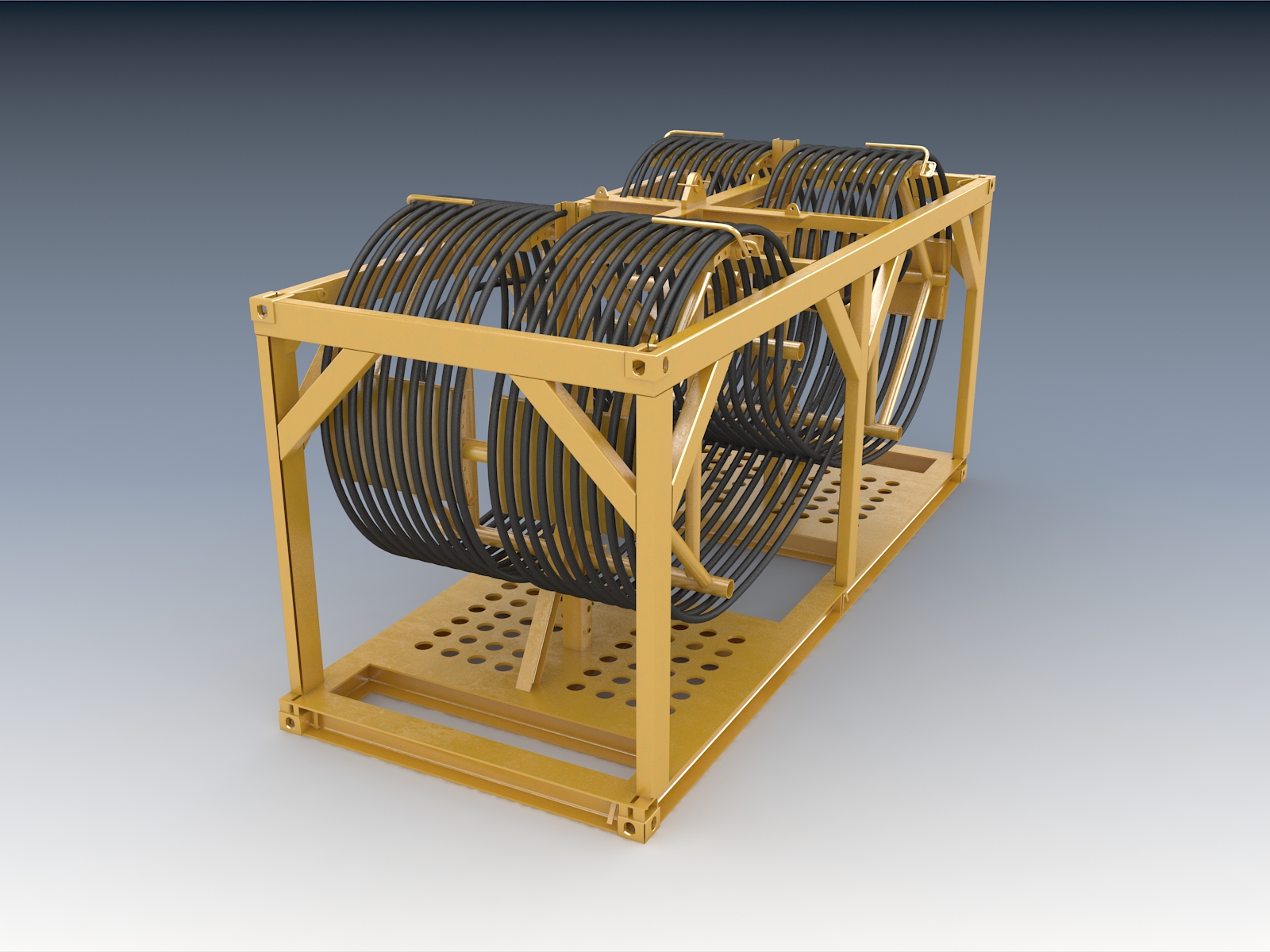

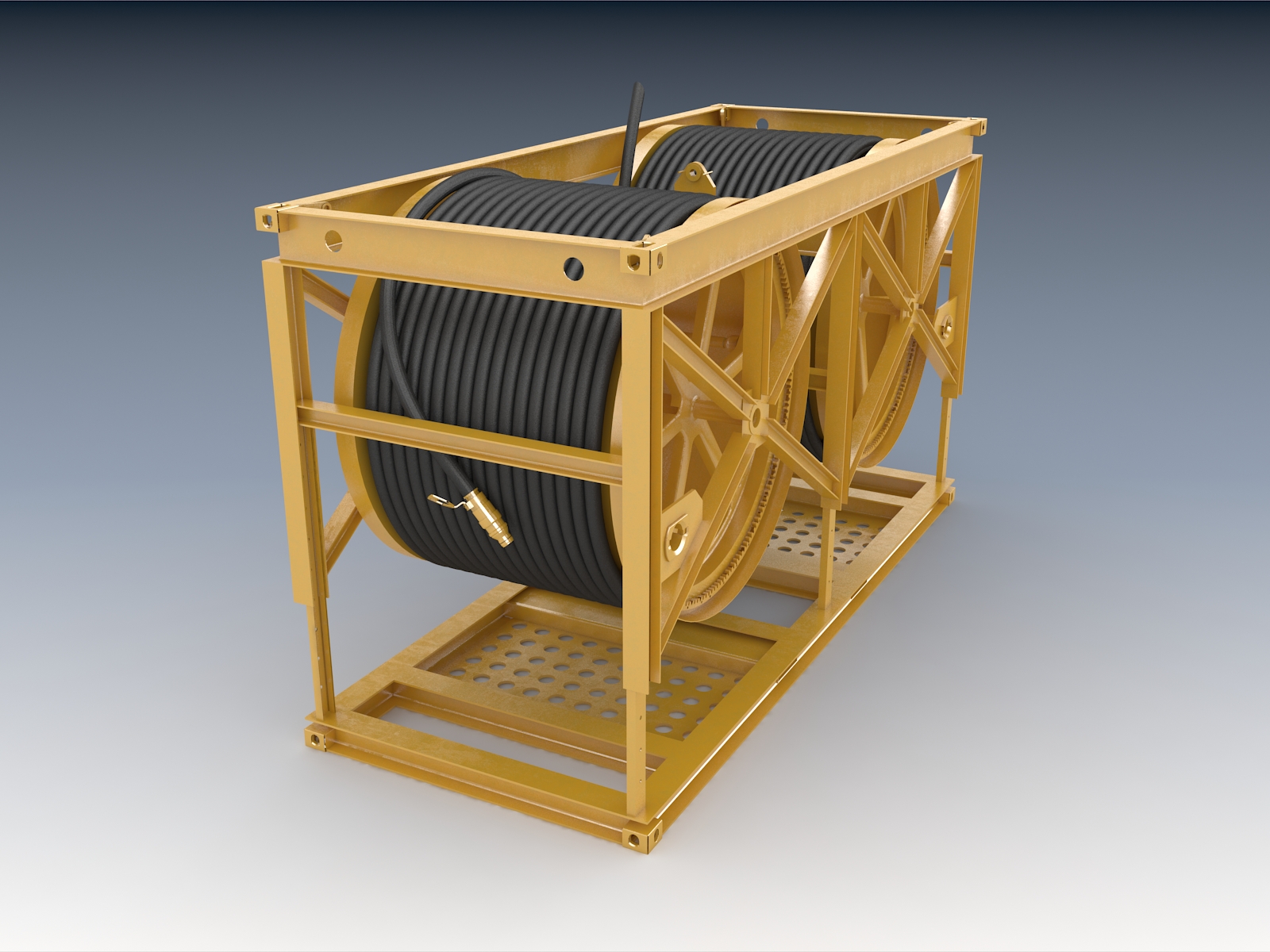

Flexible Flowlines Load out

1IN FLDR

2IN FLDR

Accumulator

CDA

CDA

FLET

FLET simplified

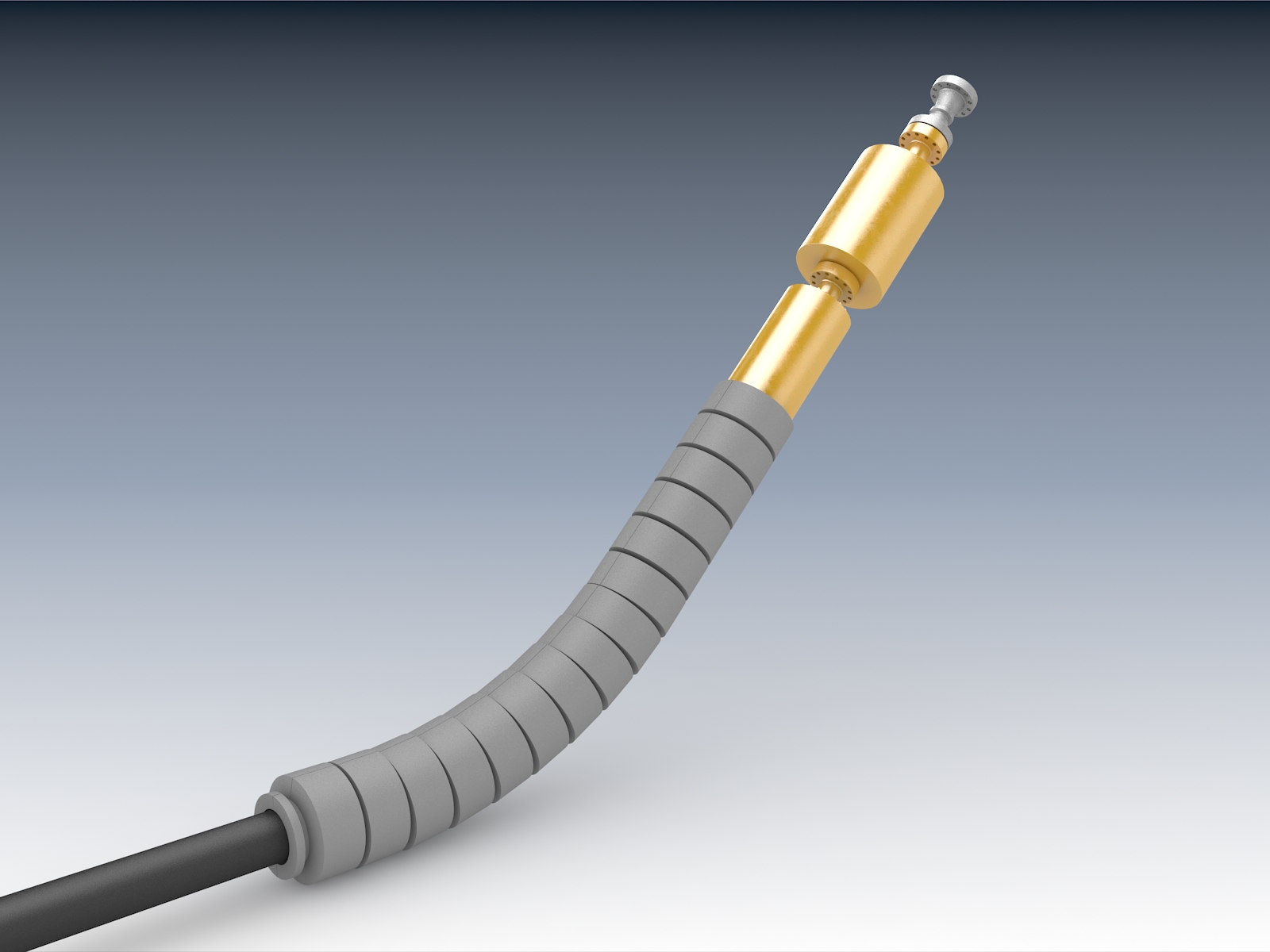

Flowline Connector

Flowline coupler

Flowline reel

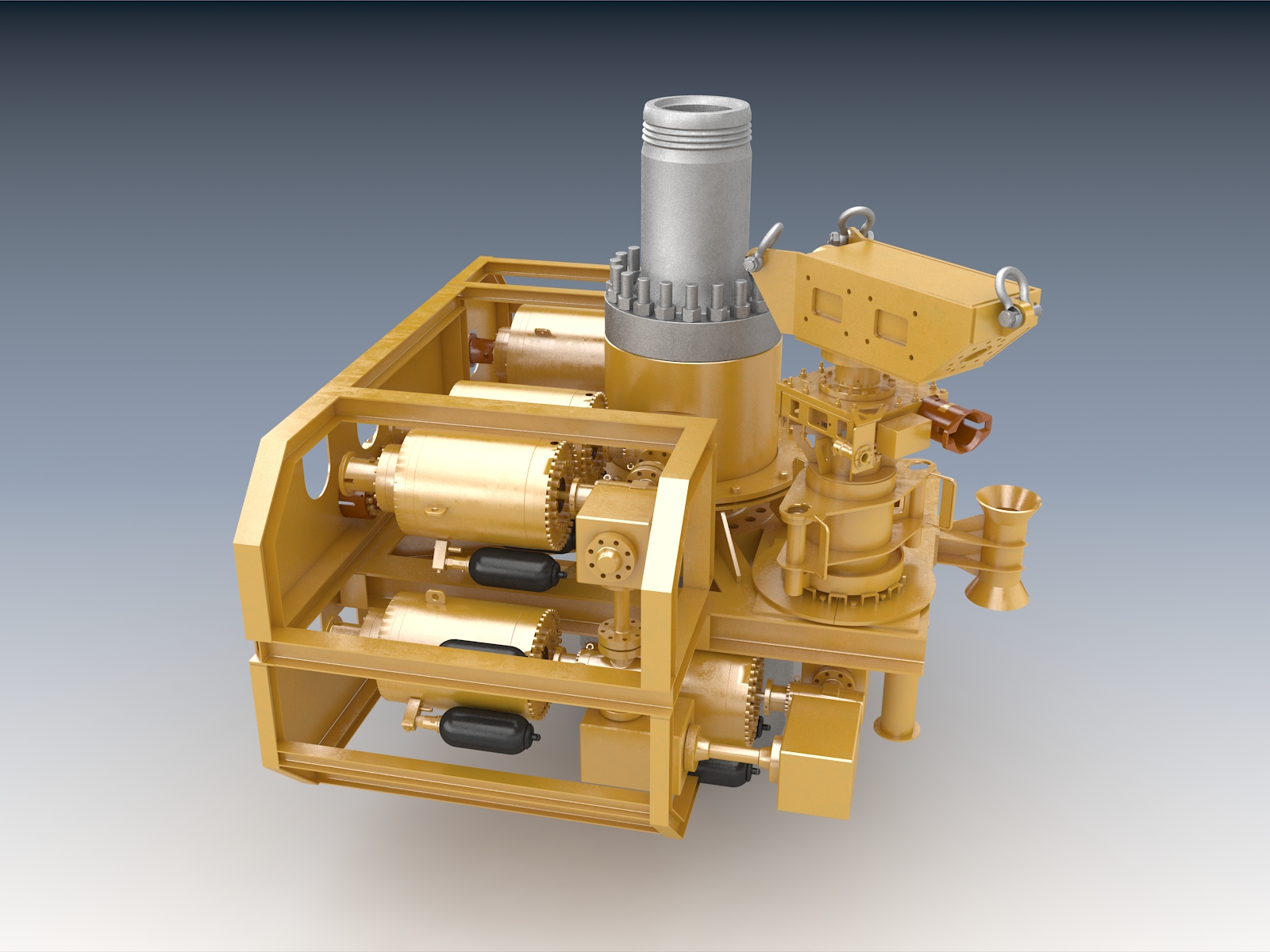

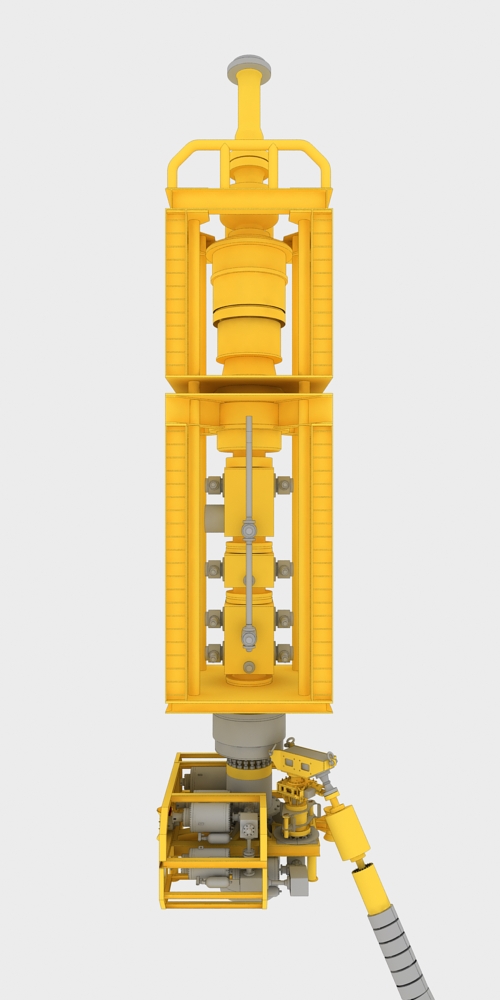

Flowspool

Flowspool Cut-away

Flowspool Cut-away

Hose End Valve

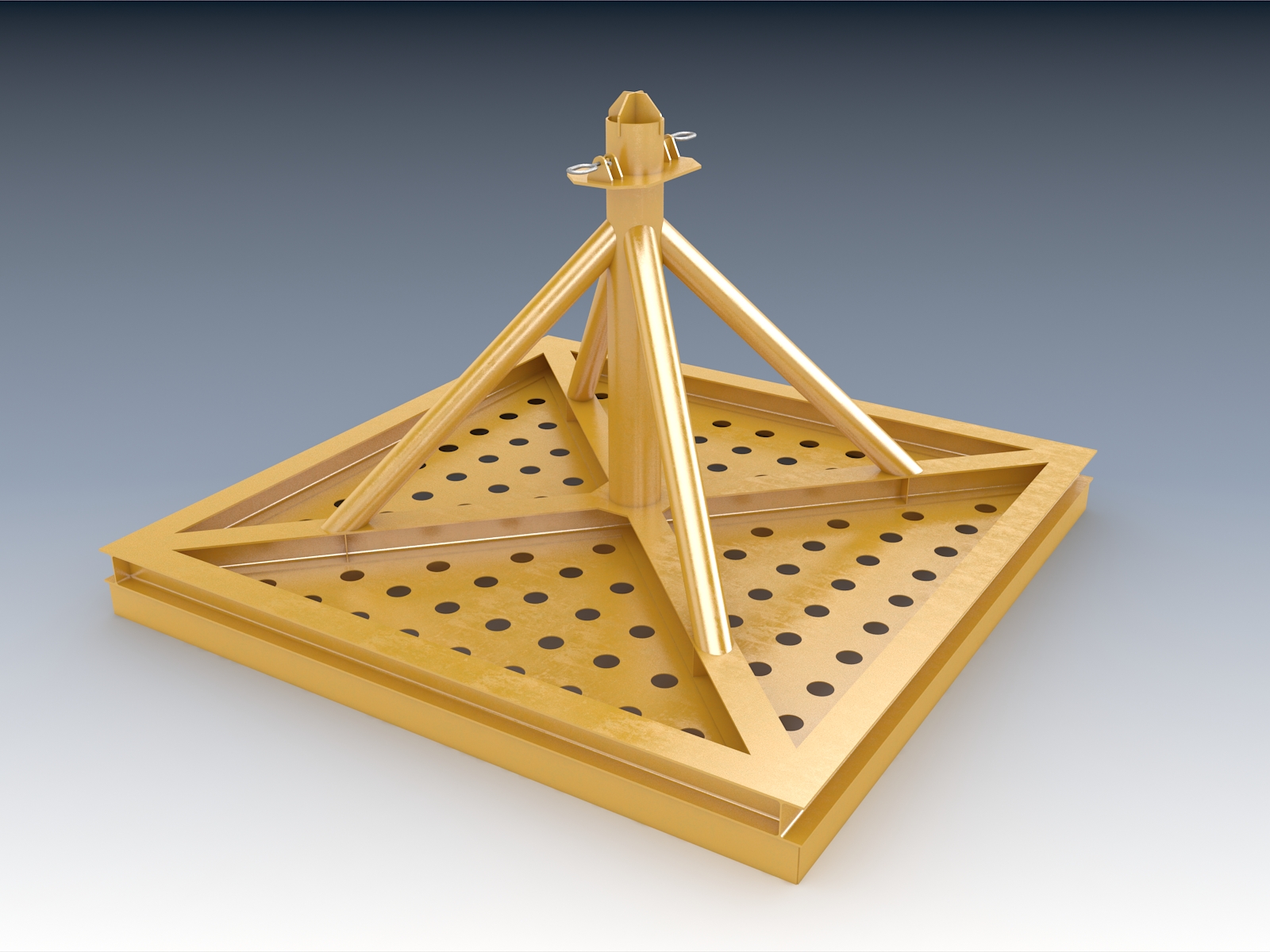

Wellhead Foundation

Wet Parking Stand

Equipment 3D models

-

2-slot BDT -

6-Slot BDT -

Capping stack connector -

Choke Connector -

Class 4 TT -

Class 5 TT -

DSTI skid -

LH Soft Land -

RH Soft Land -

SWiwel with ROV Panel -

Seal Tool Handle -

Swiwel with ROV Panel -

CDA -

CDU -

1IN FLDR Technical -

1IN FLDR simplified -

2IN FLDR Technical -

2IN FLDR simplified -

FLET simplified -

FLET technical -

Flowline coupler -

Flowline jumper connector -

Flowline reel -

Flowspool simplified -

Flowspool technical -

1 in hose with 90 deg bend and straight end -

2 in hose with 90 deg bend and straight end -

A OAS 1 in stab with hose -

A Unitech 2 in Stab with Hose -

Hose End Valve HEV -

IPHU -

Stand Structure Assembly -

TEI-101130-00 Mudmat Interface -

Wet parking stand -

UTH -

Latch and wellhead foundation -

Wellhead foundation